Key Features and Specifications

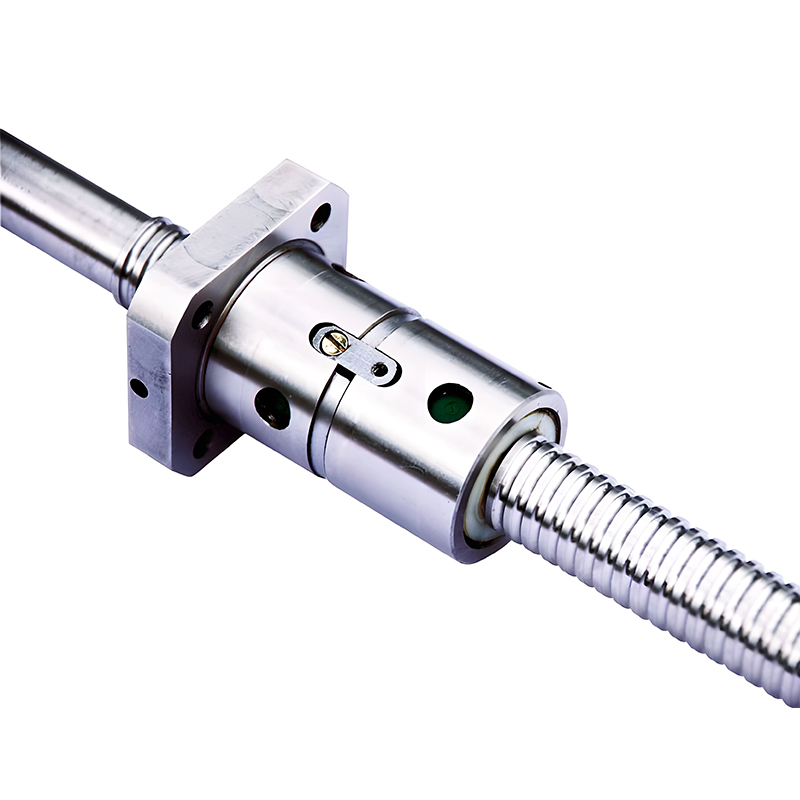

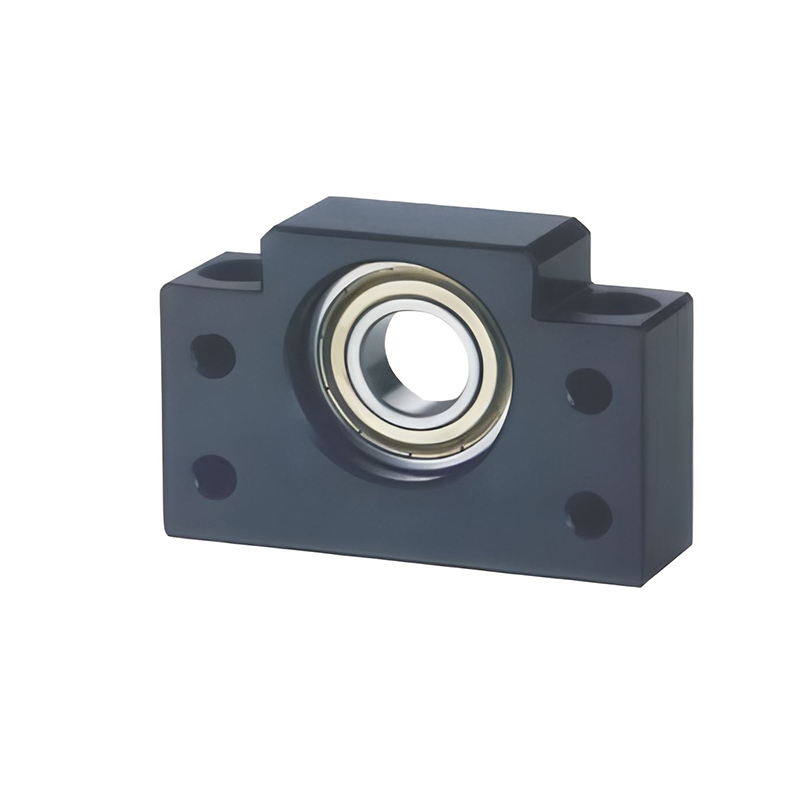

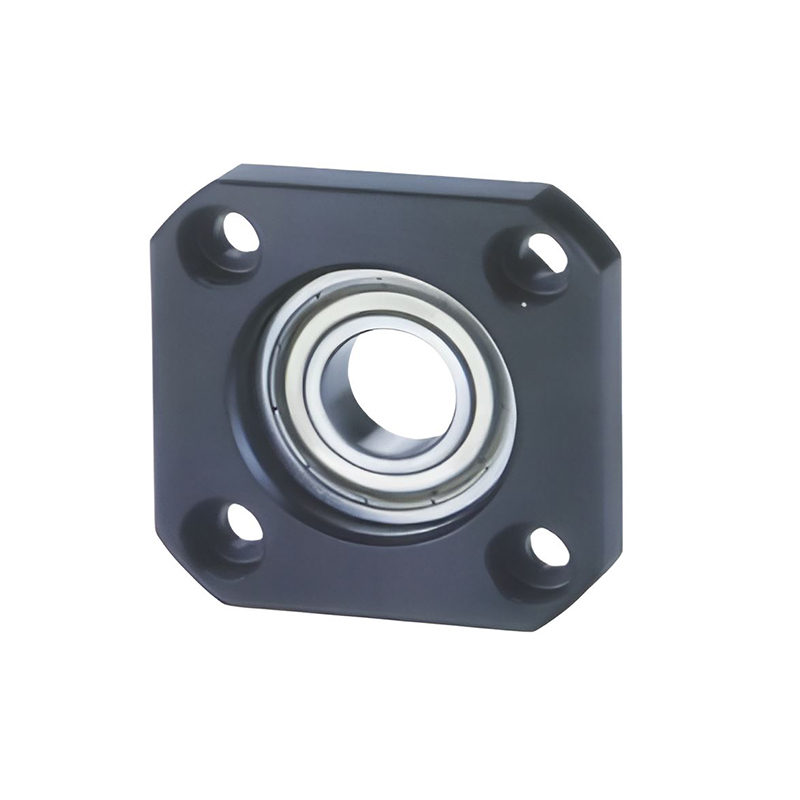

The High Precision Single Axis Robot Ball Screw is manufactured using advanced materials and precision engineering techniques. It is constructed with high-grade steel, ensuring durability and resistance to wear and tear. The ball screw mechanism is designed to minimize friction and maximize efficiency, resulting in smooth and precise linear motion.

One of the protrude features of the High Precision Single Axis Robot Ball Screw is its ability to achieve particularly high positional accuracy. The precision-ground ball screw ensures that the linear motion is highly repeatable, with smallest backlash. This is crucial for applications such as robotic arms in manufacturing lines, where precise positioning is necessary to ensure consistent product quality. The product also incorporates advanced lubrication systems to reduce maintenance requirements and extend its operational life.

Technical Advantages

The High Precision Single Axis Robot Ball Screw offers several technical advantages over traditional linear motion systems. Its ball screw design provides a high level of mechanical efficiency, converting rotational motion into linear motion with smallest energy loss. This not only enhances the overall performance of the robotic system but also reduces energy consumption, making it a more environmentally friendly option.

Another significant advantage is the product's ability to handle high loads while maintaining precision. This is achieved through the use of optimized ball nut designs and high-strength materials. The High Precision Single Axis Robot Ball Screw can operate at high speeds without compromising accuracy, making it suitable for fast-paced production environments.

Applications and Use Cases

The versatility of the High Precision Single Axis Robot Ball Screw makes it suitable for a wide range of applications. In the automotive industry, it is used in robotic welding and assembly lines to ensure precise positioning of components. In electronics manufacturing, it plays a crucial role in pick-and-place machines, where accuracy is essential for placing tiny components on circuit boards.

In the aerospace sector, the High Precision Single Axis Robot Ball Screw is used in CNC machining centers to produce high-precision parts. Its ability to maintain accuracy over long periods of operation makes it ideal for applications where downtime is costly. Additionally, the product is used in medical equipment manufacturing, where precision is critical for the production of components such as surgical instruments and implants.

Maintenance and Support

To ensure the longevity and good performance of the High Precision Single Axis Robot Ball Screw, proper maintenance is essential. Regular inspection and lubrication of the ball screw mechanism are recommended to prevent wear and tear. The product is designed with easy access to key components, making maintenance and replacement of parts straightforward.

The manufacturer also offers comprehensive support services, including technical assistance and spare parts supply. This ensures that users of the High Precision Single Axis Robot Ball Screw can rely on consistent performance and quick resolution of any issues that may arise.

The High Precision Single Axis Robot Ball Screw is a testament to advanced engineering and precision manufacturing. Its ability to deliver high accuracy, reliability, and efficiency makes it an indispensable component in modern robotic and automation systems.

![]() +86 17398543323

+86 17398543323